Denim History

The history of denim dates back to the 1840s, when the durability of the warp-faced twill textile made it a proven choice for workwear in America.

For field workers, coal miners, lumberjacks and cowboys, denim was an inexpensive clothing option that was widely available and came in all sizes. During the California Gold Rush of 1848 to 1855, prospectors were commonly seen dressed in their denim field jackets and hip waders.

In 1873, David Jacobs and Levi Strauss registered a patent for the first denim jeans—their signature 501 jeans. The original design offered four pockets (later changed to five), with copper rivets sewn to reinforce the material at wear points. Over time, certain features changed, including the removal of rivets from the crotch area during World War II due to metal rationing and the omission of a cinch strap across the back of the waistband that allowed size adjustment. A sample page from the 1908 Sears Roebuck catalog listed "working pants, jumpers and overalls of all kinds," with prices ranging from 48 cents for a double-bib, blue apron pair of overalls to 64 cents for a pair of heavy red-back denim overalls with reinforced and riveted pockets.

As the decades passed, denim's reputation for durability made it indispensable not just for workers but also for the military. During World War II, the U.S. military adopted denim for work uniforms and utility garments, relying on its ruggedness for the demanding tasks faced by soldiers. Denim jackets and trousers became standard issue for many service members, who wore them both at home and overseas. This military application of denim reinforced its status as the fabric of choice for those who needed reliable, hard-wearing clothing in the toughest conditions.

Japanese Selvedge Denim

Japan was introduced to denim in the 1950s when American soldiers stationed there traded their Levi's jeans for Japanese provisions. Japanese weavers took notice of this rugged fabric and began producing their own denim—but with twists that set it apart from its American counterpart.

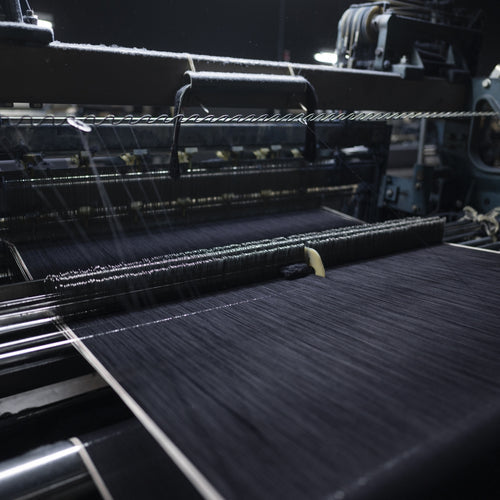

First, they used old-fashioned shuttle looms, which produced a denser, sturdier fabric than modern high-speed looms. Operating at a slower pace, these looms result in a tighter weave and the distinctive self-finished edges of the fabric, which prevent fraying and unraveling.

Second, instead of dyeing the fabric after it was woven, they dyed the yarn before weaving. This process, known as rope dyeing, involves repeatedly dipping the cotton yarn into vats of indigo dye. The dye penetrates only the outer layers of the yarn, leaving the core white. This technique results in a deep indigo blue that fades uniquely over time, as the outer dyed layers wear away to reveal the lighter core.

Third, they embraced the concept of "loom state" or "raw denim," meaning the fabric is woven and left in its natural state without additional treatments or washes. This preserves the texture and characteristics of the denim, allowing it to mold to the wearer's body and develop personalized fades and creases with wear.

Owen Stitch Signature Denim

Sourced from Japan Blue Vintage Mill

Nestled in the heart of Okayama Prefecture lies Kojima. This small town has become synonymous with heritage denim craftsmanship. Home to some of the world's finest denim weavers, including the renowned Japan Blue Vintage Mill. The craftsmen here are dedicated to preserving traditional methods while pushing the boundaries of quality and keeping old shuttle looms alive.

Crafted from short-staple organic cotton, our selvage denim is custom-made in small batches using nine Toyoda looms, each producing a mere 14 meters of fabric per day. Every running meter of fabric is self-finished with our signature red ID selvage. A slow process, no doubt, but like anything that truly matters, it's worth the time it takes.

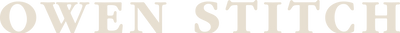

Denim Field Goods

Made in Owen Stitch

We make our denim goods the old way, the right way. We didn’t just go out and buy shiny new machines and call it a day. No, we hunted down old, forgotten machinery—the kind that’s been around longer than some folks have been alive—and brought it back to life, piece by piece. We even brought in some new tools when needed, but only if they could live up to the old standards.

This wasn’t some weekend project either. It took a full year just to get the machines right, and another to fine-tune our process, making sure every stitch, every seam, was as tough as the land we come from. Each machine we use is tailored to do one thing—produce the hardest-wearing, longest-lasting denim you’ve ever seen. That’s what we do, and we do it right. Keeping production in-house means we control every detail. We consider every aspect of each pattern, reinforcing where it’s needed most and stitching with a quality-first mindset. We don’t cut corners, because we know the people wearing our gear don’t either.

Our manufacturing line is set up for two essentials: the OC450 Jeans and the OC451 Jacket. Both are built from the same tough-as-nails tradition as denim’s origins, made for hardworking men, ranch hands, outdoorsmen, and anyone who earns their keep in the field. These aren’t just clothes—they’re tools you can trust to hold up, no matter how hard the day gets.